DatCAM designs and produces a broad range of machinery for brush manufacturers in India. Engineered solutions for special requirements are readily available. We always do this with a passion, and love for our machines. Our technology development centre is structured to provide the engineering, manufacturing, testing and management needed to produce high precision tools for a broad range of consumers.

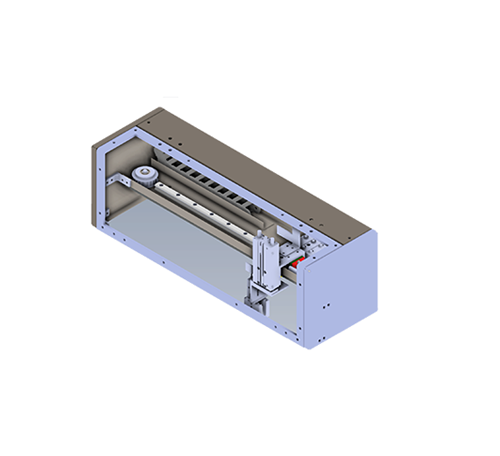

Axis 1-3 as per customer requirements

Speed 23 - 28 handles per min

Stroke Max 380 mm

Loading Capacity 400 Handles

Power Consumption 3 KVA

Air Supply 6 BAR

Weight 550 KG

Dimension D-820 x W - 1700 x H - 1720

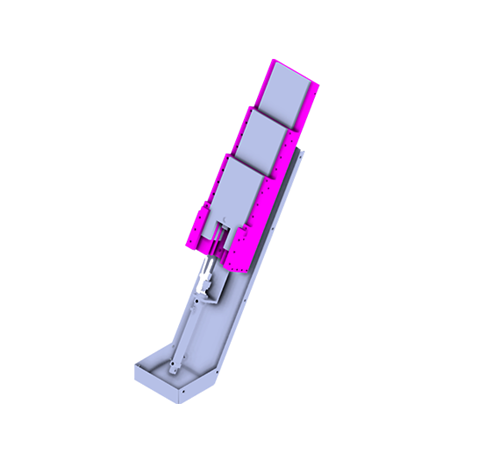

Specifically designed to achieve automatic loading of

non-bristled tooth brush (i.e tooth brush sticks /handles) in to the tufting machine.

Non Bristled Tooth brushes are feeder into the static hopper. Max of 200 -400 Tooth brush handles manually. Whenever the hopper goes empty it is detected by a sensor that is placed just above the hopper. From the hopper tooth brush is fed in to Step feeder in a step wise manner. Then the step feeder will carry this tooth brush and drop it in the walking beam.

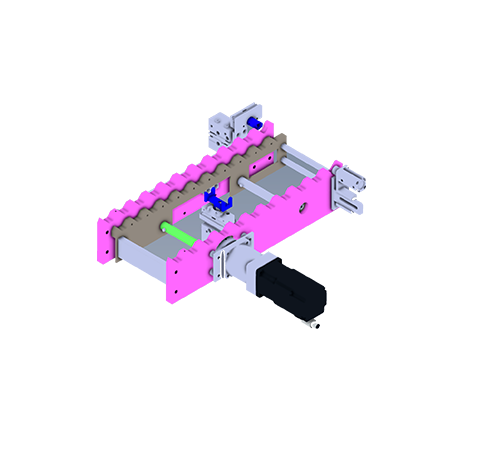

Indexing of 0-360 degrees is made using Servo motor, Pneumatics, Camera and sensor are used to place the tooth brush handles in proper Orientation and twitching alignment. Camera checks two positions of the Tooth brush handle. One is orientation and the other is head direction of the Toothbrush handle. Once the toothbrush checks for the Orientation. Next brush comes in to the position for being checked by the camera.

Once the tooth brush handles reaches the last teeth position of the walking beam, Gripper picks the Tooth brush handle and places in the Tufting machine magazine and returns to its original pick position at a very high speed of 1400 RPM in less than two seconds. Servo motor with customized belt mechanism is used.