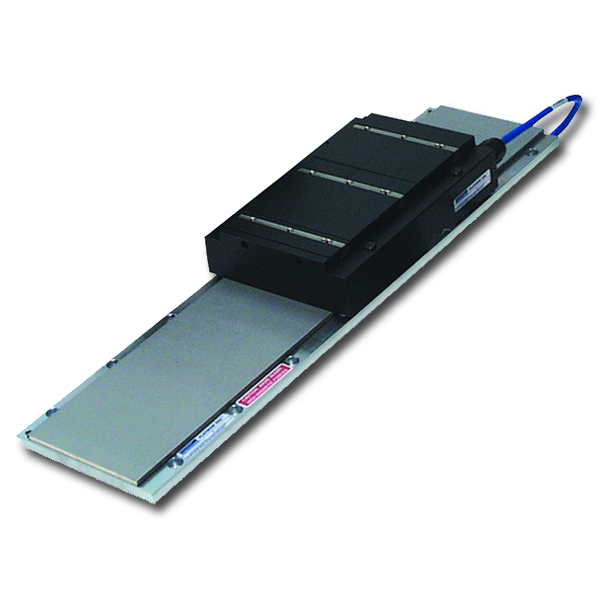

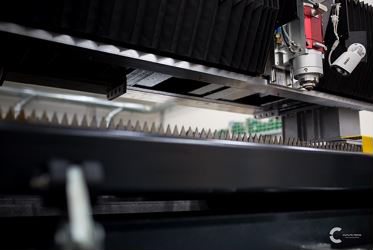

A Direct Drive Linear (DDL) motor is basically a rotary motor that is laid out flat and directly coupled to the driven load. By eliminating mechanical transmission components, this design delivers exceptional performance, stiffness, dynamic speeds and accelerations, positional accuracy, and throughput. DDL motors also enable compact mechanical assembly, quiet operation, zero maintenance and smooth, error-free motion.

By directly coupling the load to the motor you will see improved positioning accuracy, speed regulation, and reduced energy usage, all resulting in a higher performing machine.

Reduce the complexity of your machine's design. Directly driving your load by removing failure prone transmissions will decrease the likelihood of costly failures and reduce the need for expensive preventive maintenance. The end result is a reduced total cost of ownership in your machine.