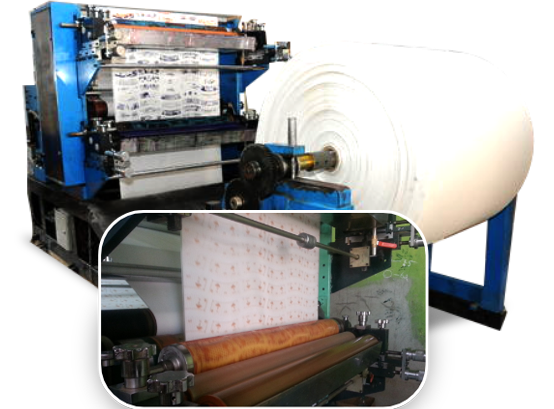

The objective of this machine is to produce paper cups by blanking as per customer defined sizes.

This machine produces a variety of color combination or as plain standards.

The procedure of the machine is to in feed the paper raw material, and thereby the process of

Tension control, color synchronization and blanking process happens.

This over all process is an closed loop system with integrate motion controller. All accessories and

punches/ die are provide along the machine for different size and patterns.

These machines are provided with a sensor system for multifunctional operations. Customized

solutions can also be provided to customers as per their requirements

The output products are used for tea, coffee, milk cups etc

Axis Single / Multiple

Speed 380 RPM

Machine Type Plain/Color

Cup Size 65ml to 240ml

Power Consumption 5 KVA

Op Production 22000 Cups /HR

Machine Weight 2 Tons

Tension controller is based on servo system. This is a close looped system. Depending upon the feedback from sensors, the machine adjust the paper supply to cutting area. This type of tension control system can control unwind and rewind zones.

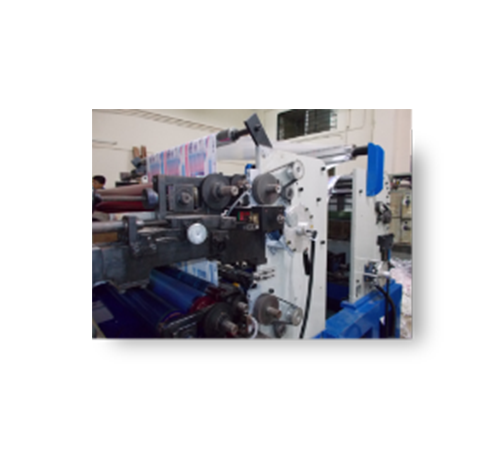

The process is multi color synchronization with servo based automation to match the demanding accuracy and precision. The major part of this sync is based on the sensor which predefine the processing. Valued design were once taught using teach-in programming.

The feeder section helps to sync paper as per the roll present in the machine. This is a continues process, and thereby an VFD is placed for the synchronization. This is also a closed loop process with the FB from sensors present.

The particular section adjust the color percentage and makes the printing mark. The papers are adjusted as per the defined value in a short period of time. The banking section cuts the paper with an micron level accuracy. High presided servo motors are used.

This Electrical panel consists of a Kollmorgen Motion Controller (PDMM) with remote IO modules for panel space saving. Kollmorgen Servo Motor with a suitable amplifier is used to define paper alignment depending upon the paper length. Three Schneider VFD are used for different operations. VFD 1 is used for feeding the paper inside the machine. VFD 2 is used for punching the paper with the help of DIE .VFD 3 is used for LH and RH paper alignment. P&F colour sensor is used when printing mode of operation is added. Schneider HMI is used for observing the machine operation. They have predefined recipes for different paper operations. Thereby the end user can select recipes easily.