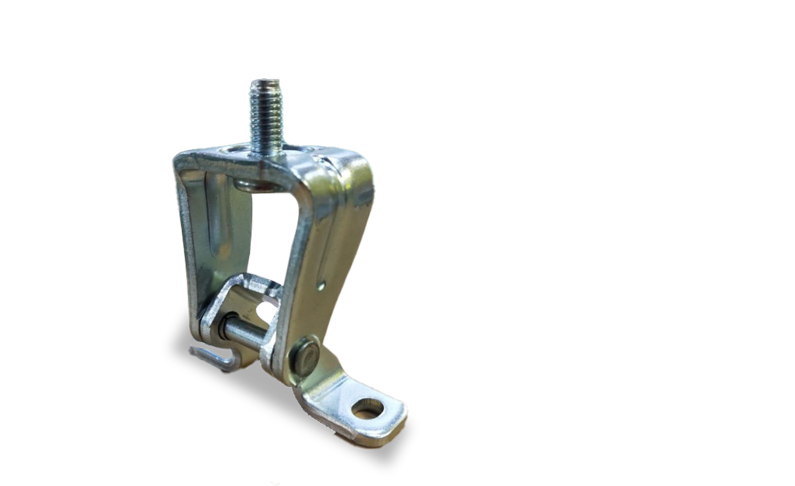

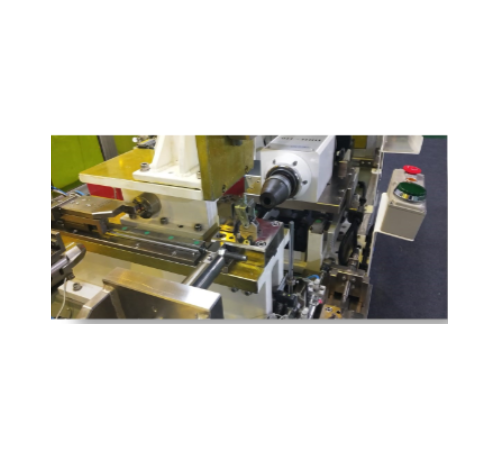

This machine is especially designed to rivet car Rear door hinges of three specified models as per customer requirement

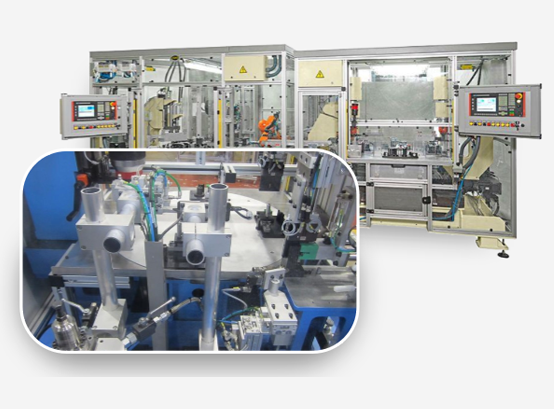

This machine is designed to assemble and rivet tail gate hinge with high speed servos. There are three stages for the specified machine. The defined three section differentiate us from all

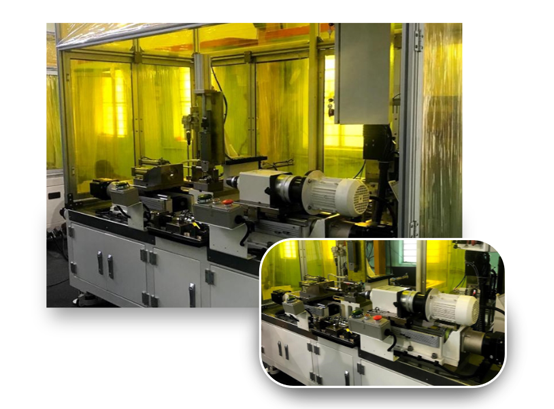

Axis 2 Axis Synchronization

Speed 8 sec per output

Loading Capacity Customer Defined

Power Consumption 3 KVA

Air 4 Bar

High production rate 450 parts/hour

Subjected bushes are dropped inside the bowl feeder, these bushes will be inserted in the bottom of the component in the specified location.

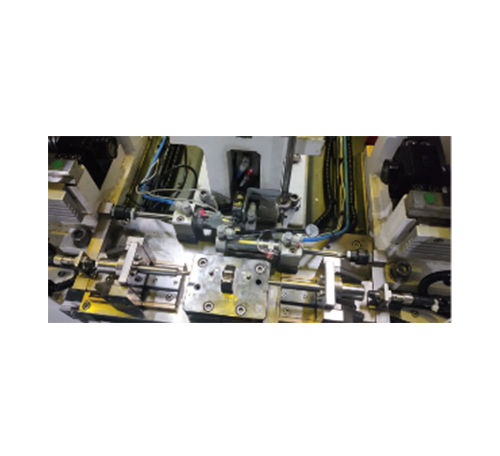

Bush Presence will be checked in this station before the reverting operation.

Pins according to the model selected are dropped inside the hopper and they will be positioned and transferred by servo motors. Once the pin is instead into the hinge via servo transfer system, reverting is completed via reverting servo motor.

The electric panel is controlled by LS PLC with a remote IO Module for saving the panel space. Mitsubishi servo of 2 nos are used for pin collection and insertion and other servo is used for riveting the hinge according to the model selected. Keyence LVDT is used for distance measurement units. Variable frequency digital controller with SIEMENS motor is used in vibrator for the process of riveting. All pneumatic operations are controlled via SMC cylinders. The flow range is also controlled by SMC valves.